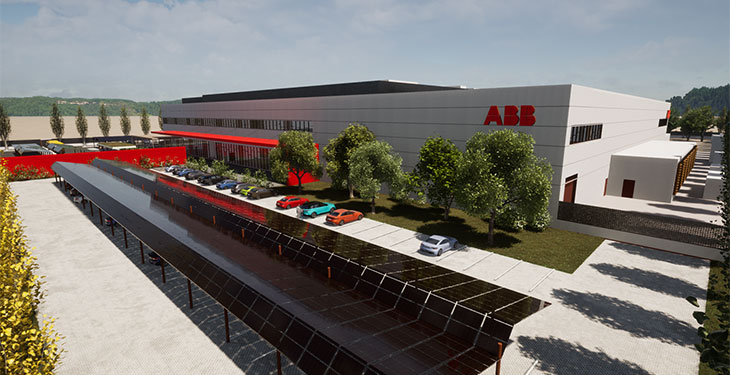

ABB has marked the start of construction at its new facility in San Giovanni Valdarno, Italy, which will serve as a global Center of Excellence and production site for electric vehicle charging infrastructure. The 16,000 square meter facility is expected to be operational by the end of 2021.

As a global market leader in e-mobility solutions, the $30 million investment in this new facility is further evidence of ABB’s continued commitment to driving innovation in this fast-growing sector. It follows a $10 million investment in a new fully sustainable, global e-mobility headquarters and Research and Development (R&D) center built on the TU Delft Campus, Heertjeslaan, Netherlands which is set to officially launch later this year.

The new plant will produce ABB’s entire portfolio of direct current (DC) electric vehicle battery chargers, from domestic systems to systems for installation in public areas and those dedicated to urban public transport. It will also help to further support ABB’s growth and innovation in the e-mobility sector.

Giampiero Frisio, head of ABB’s Smart Power Division comments: “Today represents a significant milestone in our e-mobility business. At ABB we have been driving progress in the sector for more than a decade and this new state of the art facility will contribute significantly to further advancing the global move towards zero-emission electric mobility.”

The new facility will be characterized by the integration of ABB AbilityTM digital solutions. They will allow complete visibility and optimization of the production of every individual product and interconnect automated warehouse management systems with factory departments. Automated equipment for the assembly of printed circuit boards and monitoring and testing systems will be connected to the factory information system.

R&D activities will take place in a dedicated 3,200 square meter space for development and prototyping. They will focus on the implementation of innovative solutions, new software and product life cycle management tools to fully integrate R&D activities with manufacturing activities, both internally and with external electronic manufacturing services.