The manufacturer of ceramic blocks Cemacon SA and the energy services company Servelect from Cluj-Napoca have started the implementation of a high efficiency cogeneration project within the factory in Recea, Sălaj County. The goal is to increase the plant’s energy efficiency and reduce carbon emissions by installing the high-efficiency cogeneration unit.

The project with a total value of 9.68 million lei + VAT is co-financed by the European Regional Development Fund through the Large Infrastructure Operational Program 2014-2020, Axis 6, Specific Objective 4. Among the specific objectives of the project is the construction of a cogeneration plant with an installed electricity capacity of 1.2 MW, in order to achieve annual primary energy savings of 31.6% and to reduce CO2 emissions by a minimum of 2,777.19 tons of CO2 / year.

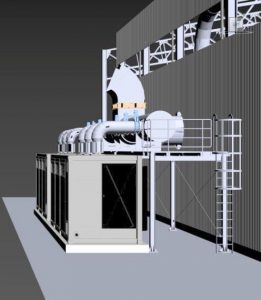

The 1.2 MWp cogeneration plant, consisting of two Capstone C600 turbine modules (2 x 600 kWp), will be used for the local production of hot air needed in the industrial process of drying the bricks, as well as the electricity used to supply factory equipment.

Capstone technology is mature, with over 5 million operating hours worldwide, Servelect said in a press release. Capstone turbine cogeneration solutions use one-piece air cushion bearing technology with no moving parts, no lubricating oils and no friction in operation. Thus, wear is minimal and operating costs are lower than with other technologies.

Servelect is the only distributor in Romania of US Capstone cogeneration turbines. The applications start from 30 kWp and reach 30 MWp in a modular system.

Applications where the implementation of turbine-based cogeneration reduces consumption, costs and emissions are those that use hot air / steam / hot water / chilled water / cold and electricity at least 4,500 hours per year.

Capstone turbine cogeneration solutions offer a wide range of applications for the oil and gas industry (for all stages of production Upstream, Midstream and Downstream), treatment plants, slaughterhouses, dairy industry, beer industry, processing and preserving fruits and vegetables , production of dehydrated food, production of medicines, production of brick, sandstone and BCA, paper industry, production of silicates, production of bedding for cats, office and residential buildings, swimming pools, data centers, hospitals.

With over 51 years of experience in the industry of construction materials, Cemacon is the largest manufacturer of ceramic blocks with Romanian capital and the leader of the ceramic blocks market in Transylvania.

The company operates 3 large production capacities located in Sălaj County, Romania, two brick and one lintel plants, and provides innovative products that add value to users, obtained at very competitive production costs. In recent years, Cemacom has made investments of over 10 million euros in technology to increase operational efficiency, innovation and for the development of the portfolio of products and services. An example is the launch of the EVOCERAMIC VB range, the only bricks with integrated basalt wool made in Romania, which insulate sound and heat without the need for additional insulation of facades.

Servelect is an energy services company (ESCO) from Cluj-Napoca, with over 15 years of experience in identifying and implementing solutions for optimizing energy consumption and, implicitly, operational costs. Servelect’s mission is to support industry and local communities in Romania to become more efficient, through integrated sustainable energy projects, so that, together, they have a positive impact on people and the environment.